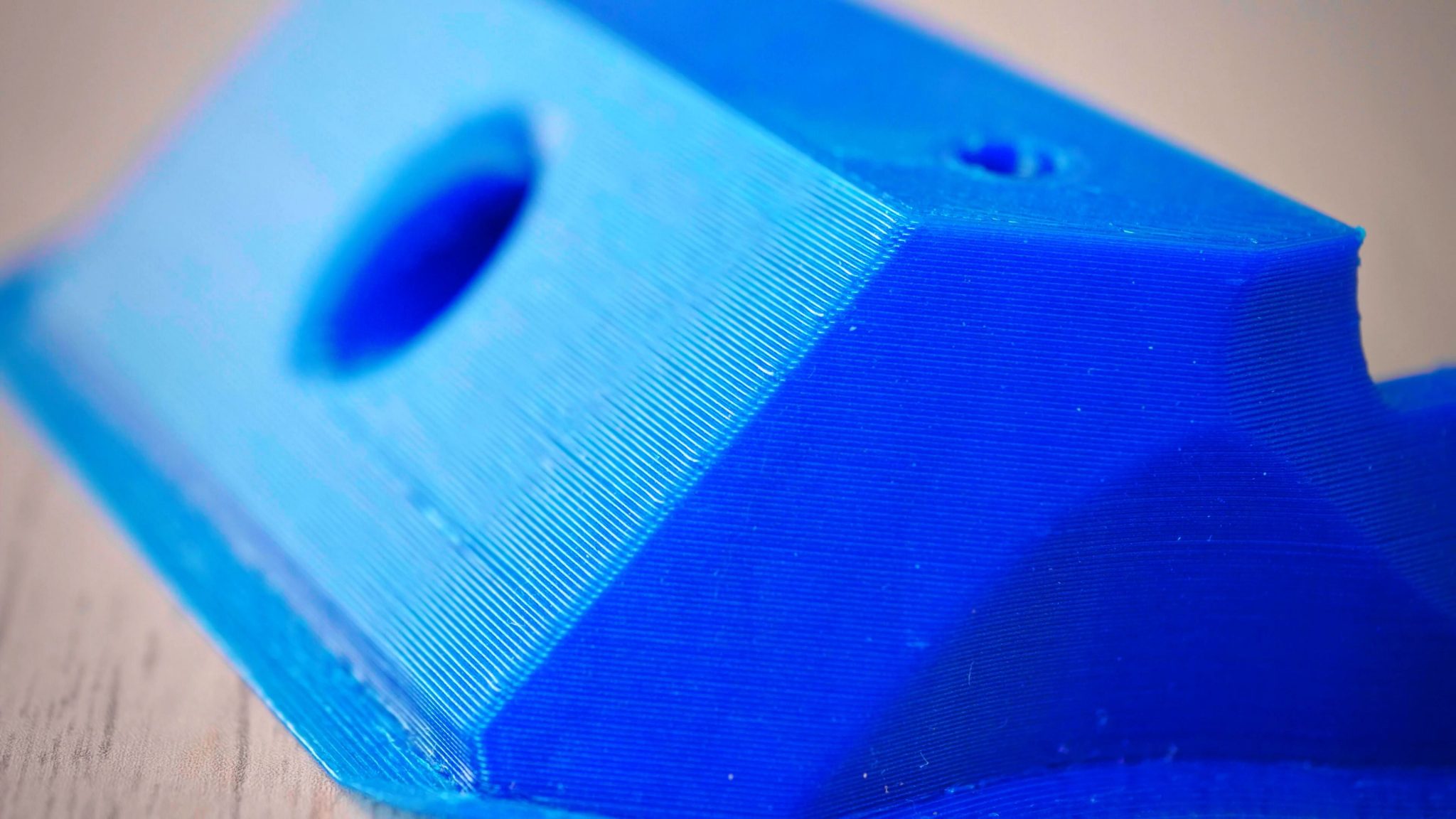

MaximumCircularRadius = spatial(1000, MM) ĪllowHelicalMoves = false // disable helical supportĪllowSpiralMoves = false // disable spiral supportĪllowedCircularPlanes = 1 << PLANE_XY // allow XY circular motionĪnd farther below that, in the functions section, paste this below the onLinearExtrude function. MinimumCircularRadius = spatial(0.4, MM) Tolerance = spatial(0.002, MM) // may be set higher i.e 0.02? HighFeedrate = (unit = MM) ? 6000 : 236 īeneath that, copy and paste this block: // used for arc support or linearization The benefits are obvious.For this line in the RRF post processor (or your own custom one): capabilities = CAPABILITY_ADDITIVE IMO it's a damn shame there isn't greater support for parametric modelling in slicers. The curves themselves are flawless on my MK3S. Probably got a few things wrong with the transitions between layers, the beginnings of the arcs are slightly imperfect, but this is a huge improvement. It's a shame, my hand programmed file is like 5% the size of the original slice, I would literally collapse hundreds of lines down to one singular arc. Fusion 360 is a cloud-based 3D modeling, CAD, CAM, CAE, and PCB software platform for product design and manufacturing Design and engineer products how you. Just download Slicer from Autodesk, and follow the install prompts. Turn off the nut and select the 4 faces of the screw thread (be careful to select all 4 faces) and assign an offset of -0.1 mm (you can adjust this for.

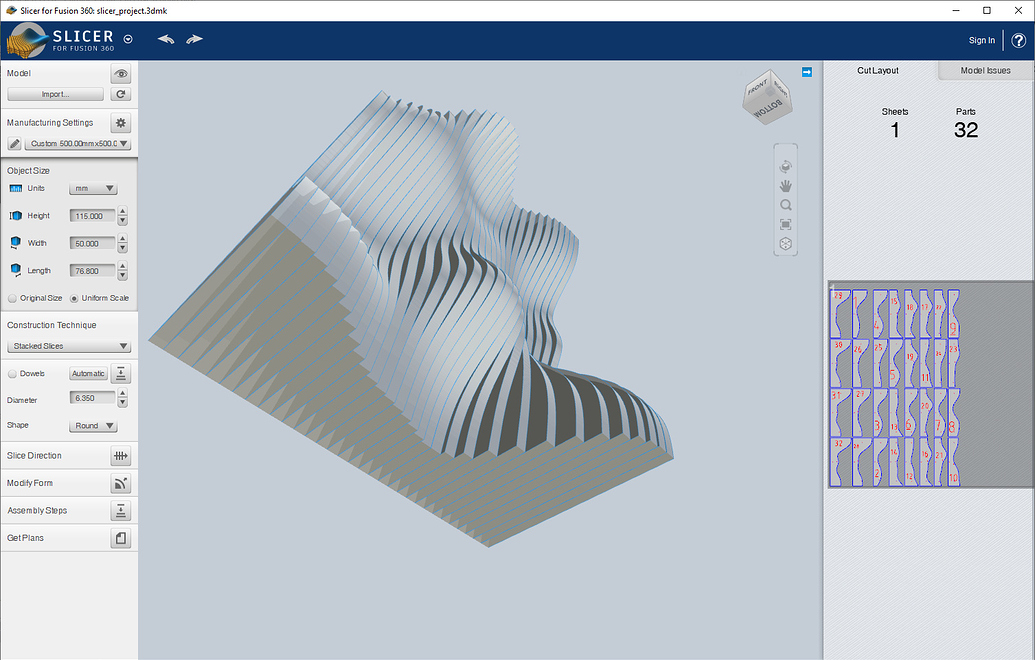

In the Modify section, select the Offset Face command. Click on the starting point of the sketch and then drag your mouse to create the desired shape. Installing Slicer for Fusion360 Installing Slicer for Fusion360 is easy. This is the most important step, from this one can obtain a functional thread for 3D printing. Fusion 360 offers a range of sketch tools, such as line, rectangle, circle, arc, and spline. Designers and anyone seeking a 3D printing software solution for their 3D modeling. The default cylinder and sphere objects that it can spawn are themselves already triangulated, even though there's no reason they have to follow the rules models loaded in from files follow.īut I think the real answer here is that if you open up a gcode with actual `G2` or `G3` commands, (I have done this with a cylinder I programmed by hand, yes it prints like a champ and took a bit of work), the Gcode viewer does not display the moves nor add the extrusions to the time/material calculations. You can choose from the X-Y, X-Z, or Y-Z plane. Following blog highlights the print preparation functionality Sualp O.

Open your file with Slicer for Fusion 360 software 1.2. Laser Cutting with Slicer for Fusion 360:Slice your 3D model 1.1. I would argue that PrusaSlicer flat-out does not support the `G2` or `G3` command whatsoever. Did you know that since March of 2020, fusion360 had a built in slicer for FFF 3dprinting. Slicer for Autodesk Fusion 360 Tutorial: Slice your 3D model Summary 1.

RE: force the slicer to use G2 G3 instead of G1

0 kommentar(er)

0 kommentar(er)